SIL-PAD

SIL-PAD 1200

Features & Benefits

- Thermal impedance: 0.53°C-in2/W (@50 psi)

- Exceptional thermal performance at lower application pressures

- Smooth and non-tacky on both sides for easy re-positioning, ease of use and assembly error reduction

- Superior breakdown voltage and surface “wet out” values

- Designed for applications where electrical isolation is critical

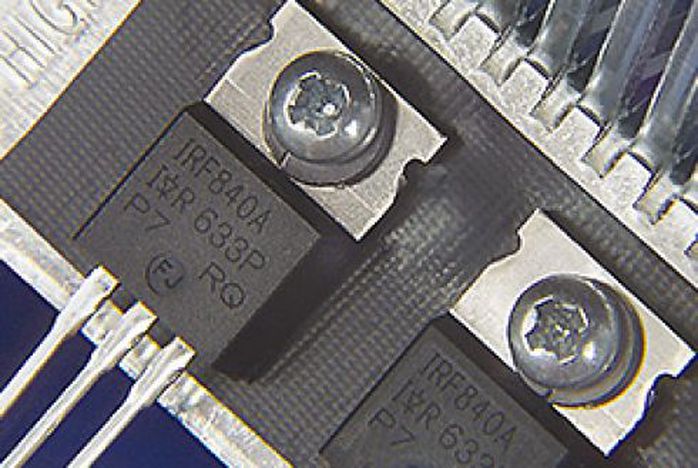

- Excellent cut-through resistance, designed for screw and clip mounted applications

Properties

| Properties | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Reinforcement Carrier | Fiberglass | Fiberglass | *** |

| Color | Black | Black | Visual |

| Hardness (Bulk Rubber) (Shore 00) | 80 | 80 | ASTM D2240 |

| Typical Use Temp (°F) / (°C) | -76 to 356 | -60 to 180 | *** |

| Thickness (inch) / (mm) | 0.009 to 0.016 | 0.229 to 0.406 | ASTM D374 |

| Elongation (%45° to Warp and Fill) | 20 | 20 | ASTM D412 |

| Tensile Strength (psi) / (MPa) | 1,300 | 9 | ASTM D412 |

| Electrical | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Dielectric Breakdown Voltage (Vac) | 6000 | 6000 | ASTM D149 |

| Dielectric Constant (1000 Hz) | 8.0 | 8.0 | ASTM D150 |

| Volume Resistivity (Ohm-meter) | 10^9 | 10^9 | ASTM D257 |

| Flame Rating | V-O | V-O | U.L. 94 |

| Thermal | Imperial Value | Metric Value | Test Method |

|---|---|---|---|

| Thermal Conductivity (W/m-K) | 1.8 | 1.8 | ASTM D5470 |

| Pressure (psi) | 10 | 25 | 50 | 100 | 200 |

|---|---|---|---|---|---|

| TO-220 Thermal Performance (ºC/W) | 2.82 | 2.64 | 2.41 | 2.13 | 1.90 |

| Thermal Impedance (°C-in2/W) | 0.71 | 0.62 | 0.53 |